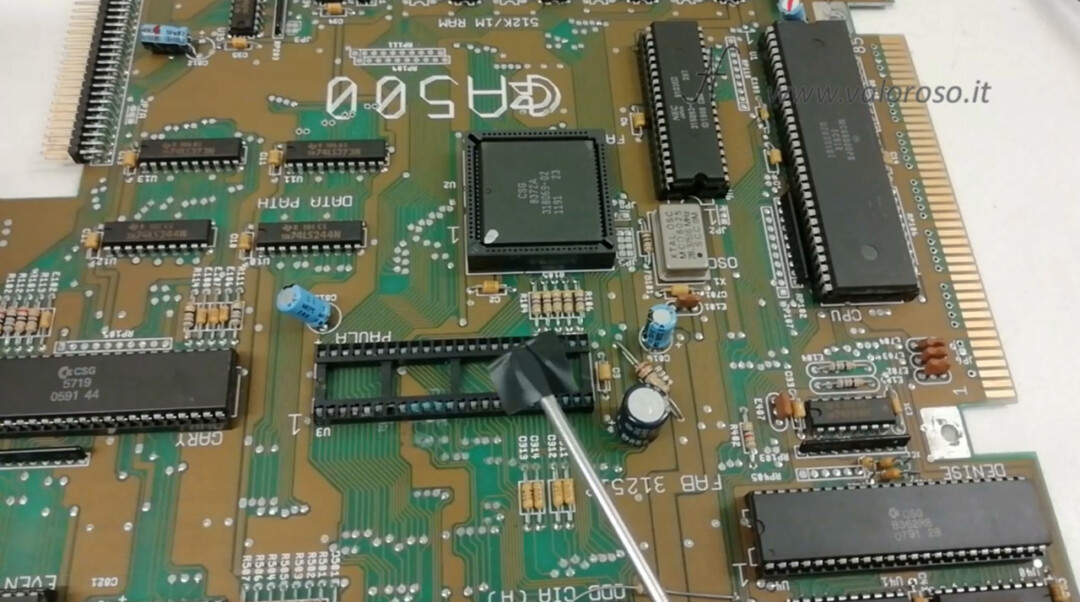

The repair of an Amiga 500 came in handy for making a tutorial on how to desolder a socket, from the PCB, with the ZD-8915 desoldering station. In the video, at minute 9:35, there is a tutorial on how to set up and use the desoldering station.

The ZD-8915 desoldering station is not very expensive and is readily available. It can be said to be a low cost desoldering station. Compared to the classic tin sucking pump, it has the advantage of being faster and heats up while sucking.

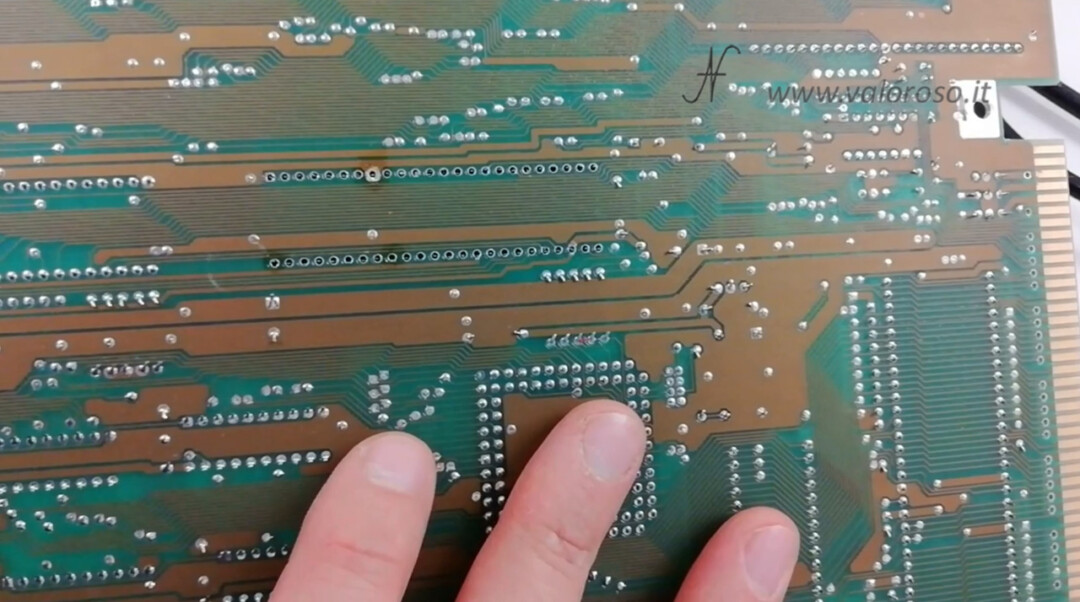

The use is quite simple, but care must be taken to correctly use the ZD8915 desoldering iron in order not to compromise the printed circuit.

If the desoldering procedure is not carried out correctly, the printed circuit boards may break or detach.

Set the temperature of the ZD-8915 desoldering station

First, let's set the ZD-8915 desoldering station to 350 °C. With this temperature, if you do not insist much on each pin, you do not run the risk of damaging the tracks of the printed circuit. If you find it difficult to vacuum the pond at this temperature, you will necessarily have to increase it.

If one or more pitches to be unsoldered are connected to thick tracks (for example the masses), you will have to increase the temperature of the desoldering iron.

Exact procedure for unsoldering a pin on an integrated circuit or socket

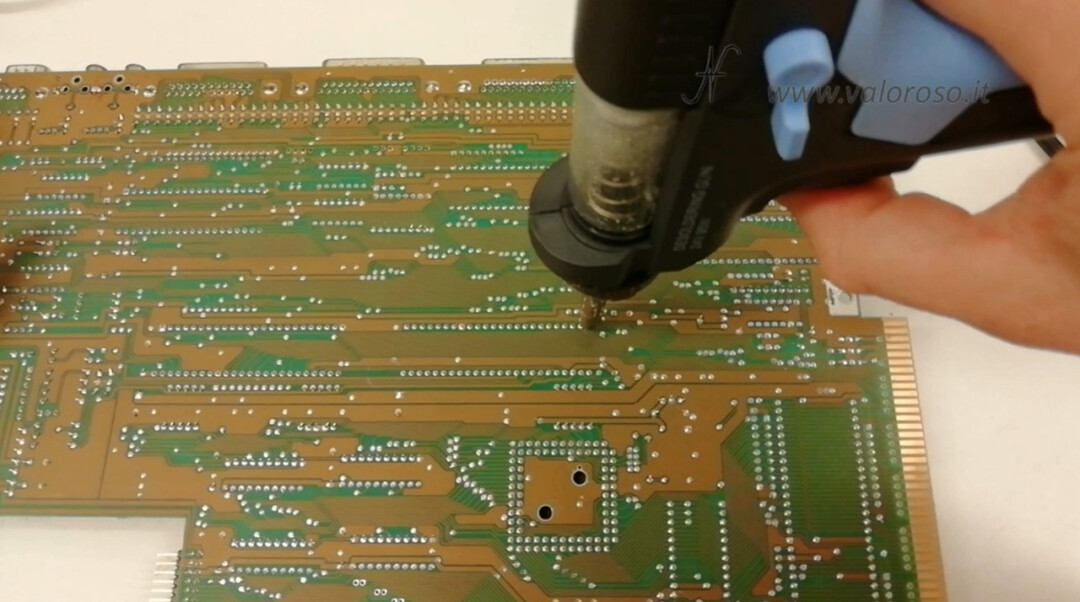

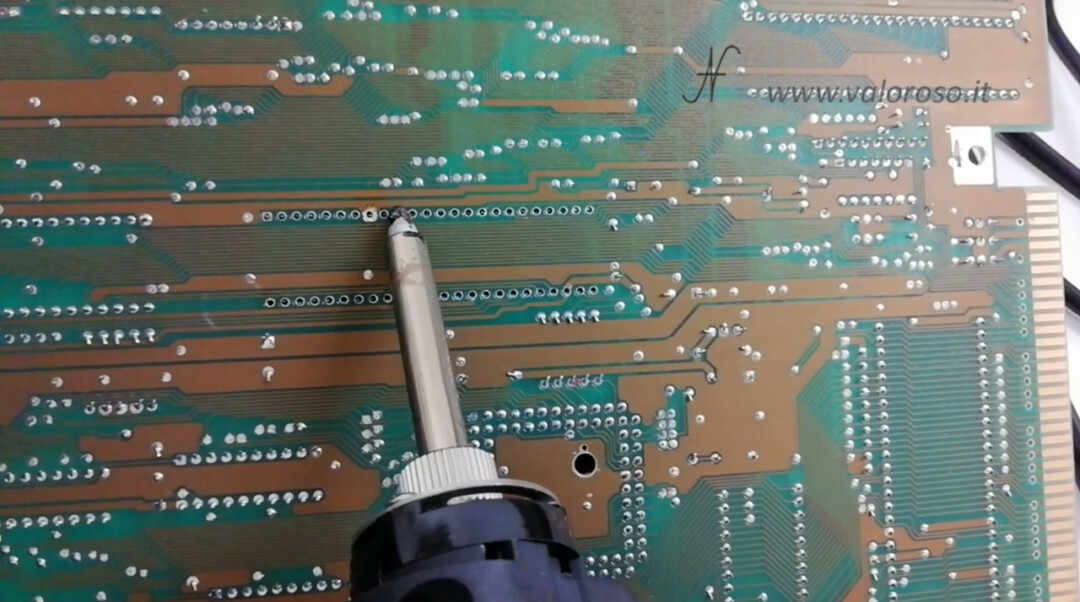

And here is the procedure for unsoldering a socket or IC with the ZD-8915 Desoldering Station. When the desoldering iron is hot (the measured tip temperature must be the same as the set temperature), you can apply the tip to the pin pad of the socket or IC.

The pin of the component must enter the hole in the tip of the desoldering gun.

While heating the foot and the pad, do not vacuum, in this first phase. You do not have to press the tip of the desoldering iron towards the printed circuit board, otherwise you risk ruining the slopes connected to the pitch. The tip of the gun of the desoldering station should only be placed on the tin present on the pitch.

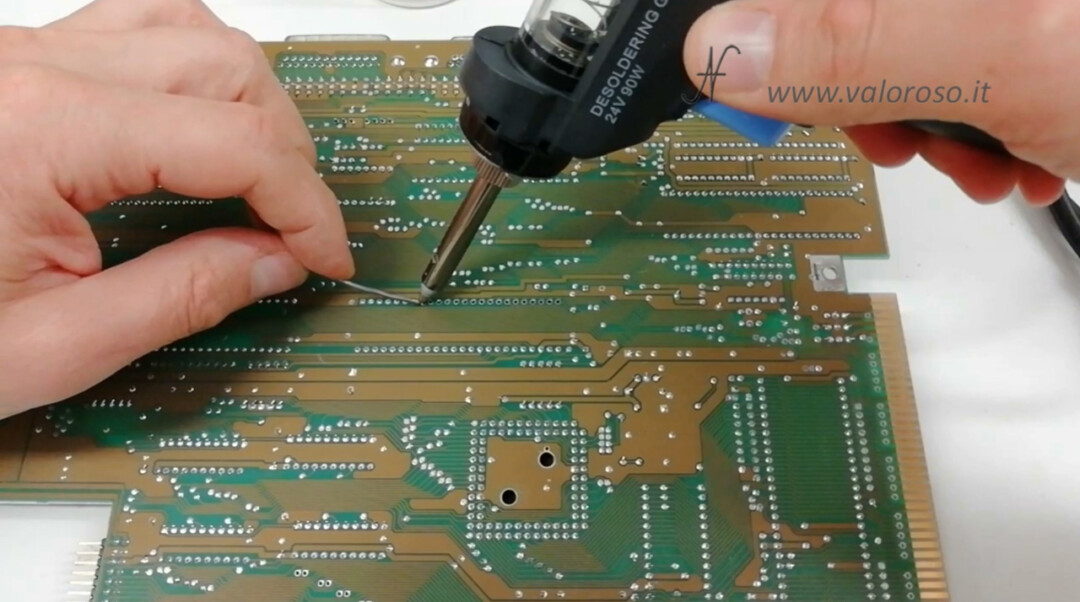

Using small circular movements, without pressing down, you must feel when the pond has melted. Initially, you will feel more resistance, because the pitch pond is still solid. Then, when the tin becomes liquid, you will feel that the tip of the desoldering iron moves with less resistance and the foot of the socket begins to move inside the PCB hole.

When you feel this sensation, you can vacuum by pulling the trigger on the desoldering gun, keeping the tip vertical. Remember to place the tip on the pitch, vertically, without pushing.

If you apply this procedure correctly, unsoldering a socket, but also a chip, from the printed circuit board, is really very simple!

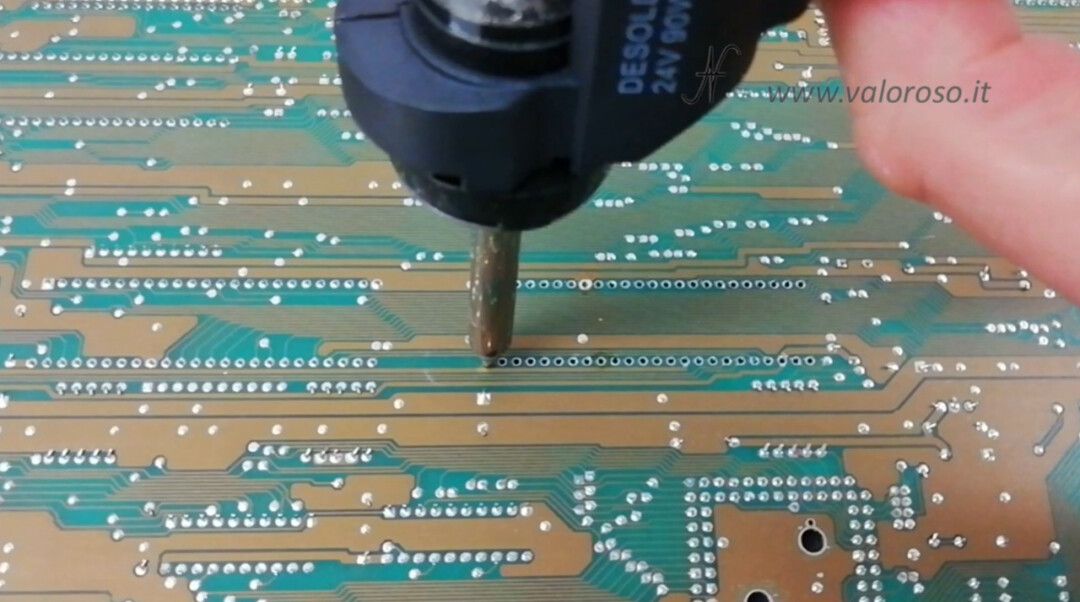

Pitches connected to very thick tracks: how to use the ZD-8915 desoldering station

On some pins, generally they are the ground ones, where the PCB tracks are thicker, it is possible that it is necessary to set a higher temperature of the desoldering station, even 370 degrees (°C) or more.

You notice this when, by moving the tip so that you can feel when the tin is melted, it always encounters some resistance and the pin does not move in the hole.

In this case, in addition to raising the temperature of the ZD-8915 desoldering station, you will need to apply a little more tin on the foot, to improve the passage of heat.

Even if one foot does not completely desolder, you will need to apply new solder and repeat the desoldering.

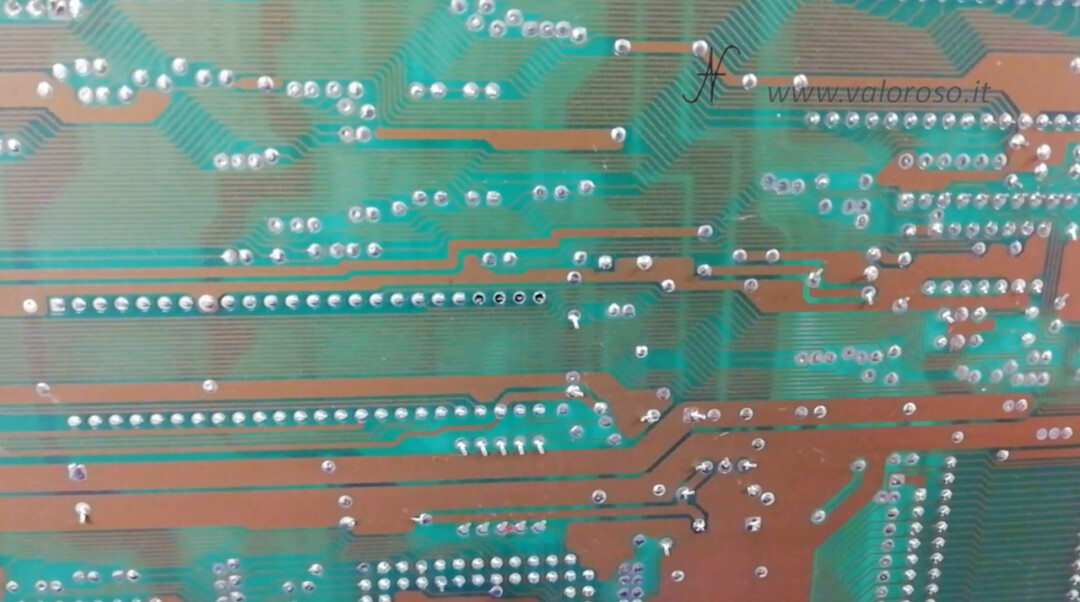

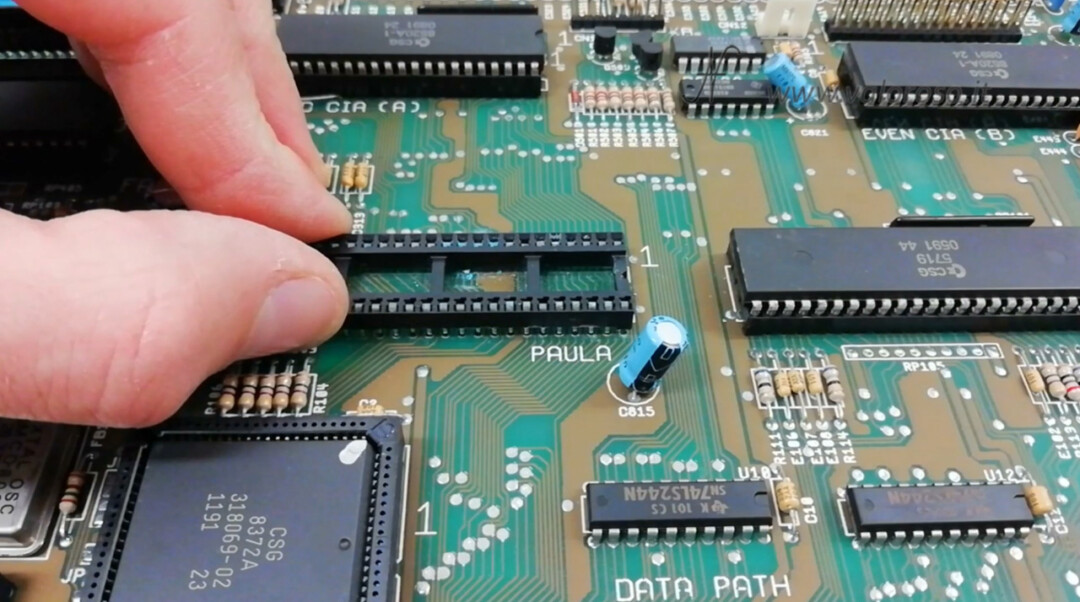

Remove the socket or unsoldered IC

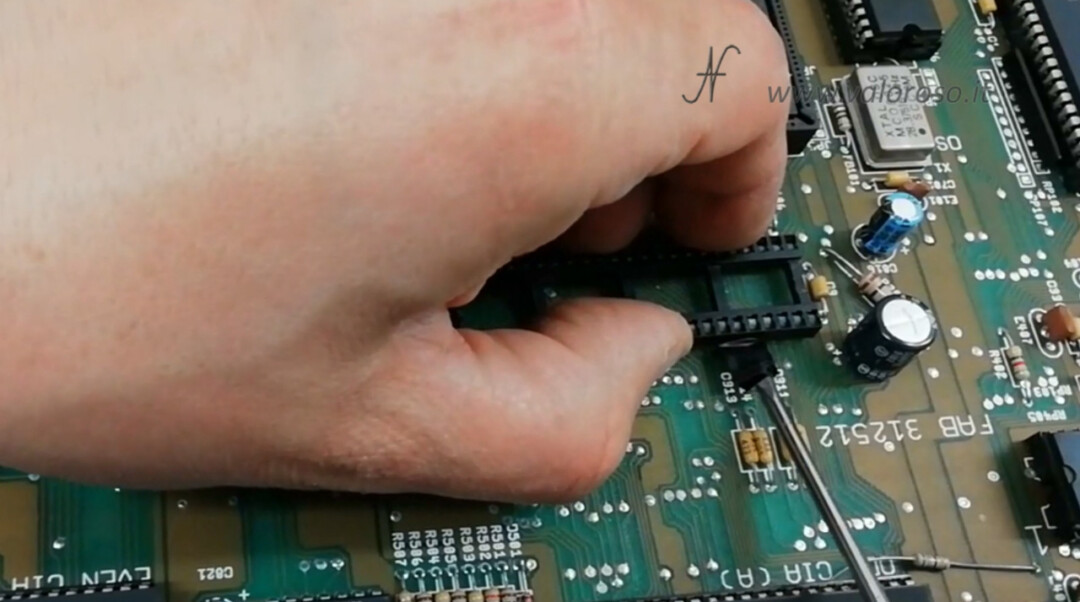

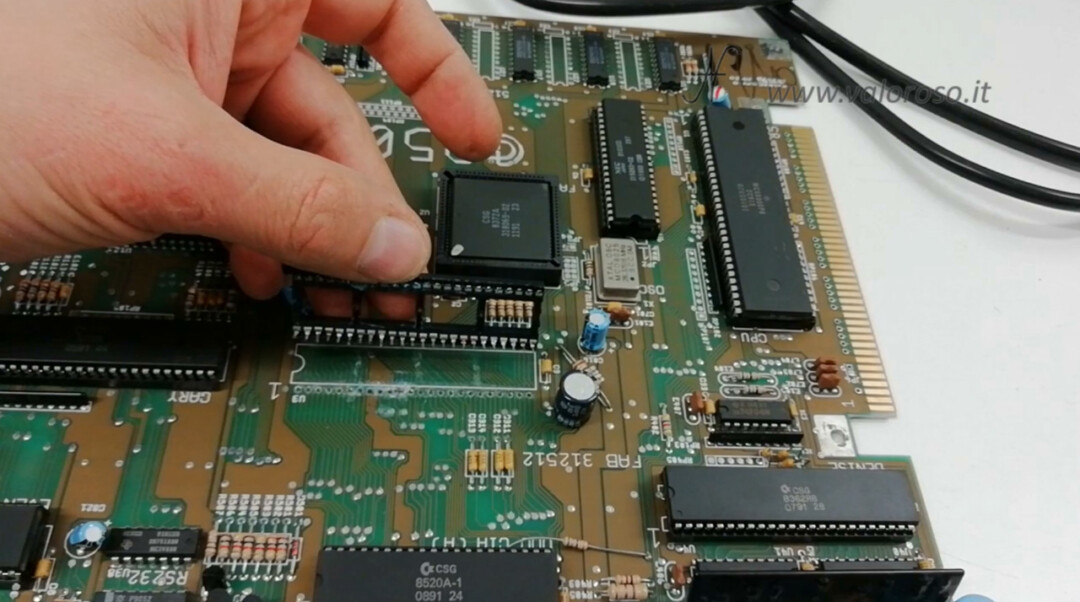

After you have sucked the tin from all the pins, via the ZD-8915 desoldering station, you can remove the socket or the chip that you have unsoldered.

Using a plastic lever, or a slotted screwdriver to which you have applied a bit of insulating tape on the blade, to avoid cutting the printed circuit tracks, you can do a bit of leverage to lift the component.

Warning! Do not force! The feet have to lift by themselves! If you see that any pins are still attached to the PCB with tin, you will have to reheat them until they come off. If, by mistake, you apply force to the lever, it could raise the pads and tracks of the printed circuit board.

The socket (or chip) should pop up without resistance.

If the socket (or chip) does not lift completely, you can watch how it behaves by moving it and checking which pins are actually unsoldered and which ones remain stationary.

The latter must be unsoldered again. Sometimes, it is enough to heat them to dissolve the small amount of tin left.

And here is our clog has been removed!

The difficulty in removing the socket (or the integrated circuit) in this case was even greater, due to the oxide affecting some contacts.

After some desoldering, the tank of the desoldering iron gun needs to be emptied of the sucked tin. If you notice that the filter has become clogged, you will need to clean or replace it.

Very good post.

It’s in point of fact a great and helpful piece of info.

I am satisfied that you just shared this useful info with us. Please keep us up to date like this.

Thank you for sharing.

Thank you!

Awesome article.

Thank you!

Hi there, I discovered your site by the use of Google whilst looking for the ZD8915 station, your website got here up, it seems good.

I have bookmarked it in my google bookmarks and found that it’s truly informative.

A lot of people can be benefited from your writing. Cheers!

Thank you!

Way cool! I appreciate you writing this article plus the rest of the site is also very good.

Thank you!

Great!!! Thank you for sharing this review.

Thank you!